VDMIS fully links CAD component data with the CMM programming and inspection process providing both precision and productivity. Standard international CAD data exchange protocols are utilized throughout namely IGES, STEP, VRML, etc.

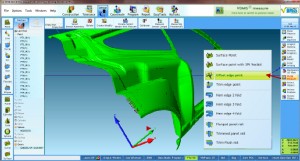

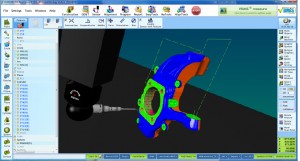

VDMIS is built with the latest generation solid modeling engine which displays the CAD model in a true solids format providing the ultimate in accuracy and enabling surface nominal data and corresponding vectors to be selected directly from the part model.

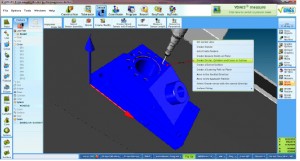

Full prismatic part geometry is available with automatic feature recognition and measurement simply by selecting the feature to be inspected with a single mouse click.

One Click to select multiple prismatic entities

Automatic Collision avoidance And sensor selection

Complete set of IAI Sheet Metal Inspection Functions including Relative Measurement