Over the last two decades, the fundamental mechanical structure of Coordinate Measuring Machines (CMMs) has remained largely unchanged. Since CMMs utilize frictionless air bearings as guideways, they do not experience the same wear and tear as high-force machinery like metal-cutting tools. This means that their mechanical components can last almost indefinitely. However, the technology surrounding these machines such as software, electronics, and probing systems has evolved significantly. As electronic motion control systems, software, and PCs become outdated, operating older CMMs becomes increasingly inefficient. These legacy systems often require expensive maintenance and service, limiting productivity and increasing operational costs.

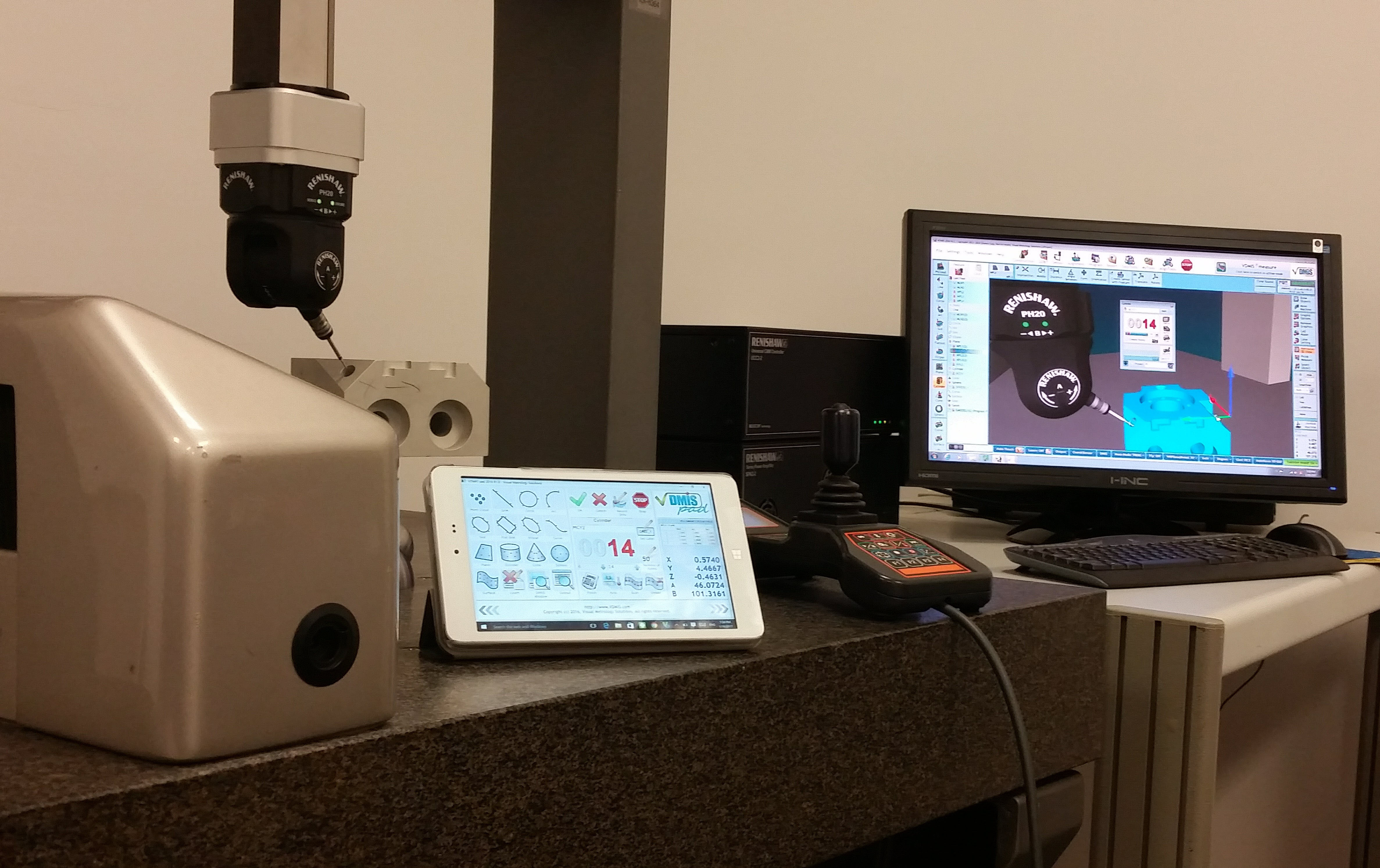

Software is the main component of a CMM. Since it is the primary interface for operators, outdated or inefficient programs can lead to slow performance, cumbersome execution, unfriendly reporting, and ultimately reduced productivity.

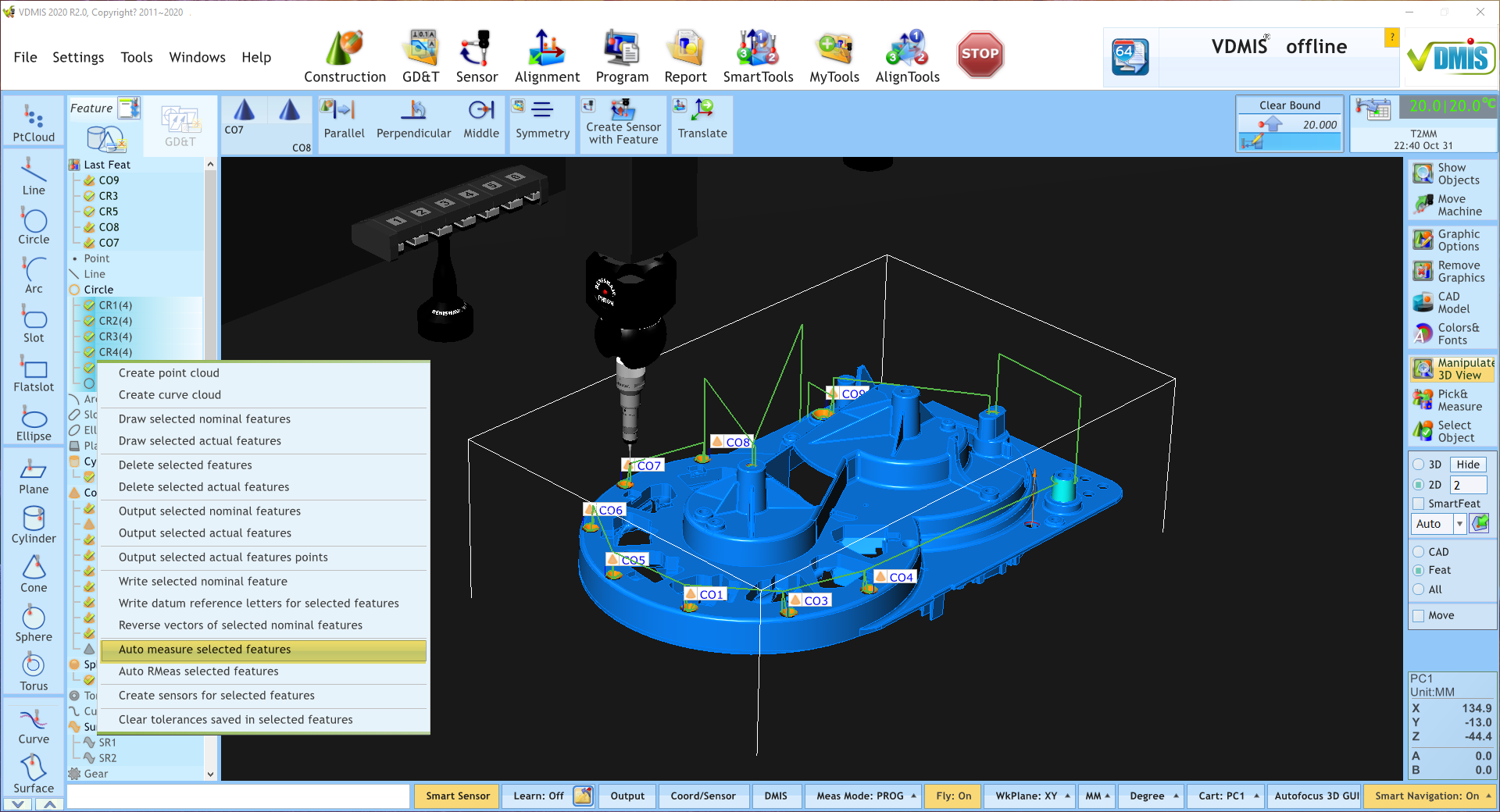

Modern metrology software like VDMIS has been developed to leverage CAD capabilities fully, allowing for rapid offline programming where nominal and tolerance data are directly imported from CAD models. This streamlines setup and reduces potential errors.

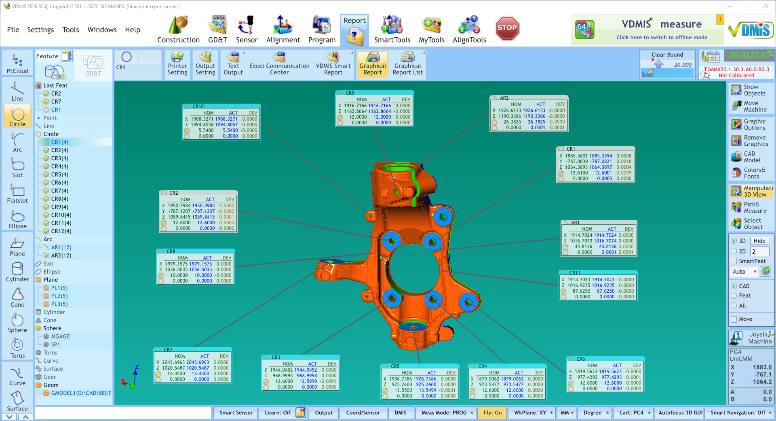

Graphic reporting has further enhanced the user experience. Graphical data is easier to interpret, enabling quicker decision-making and corrective actions based on measurement results.

Additionally, VDMIS software includes advanced features like sophisticated error mapping and temperature compensation, which improve overall measurement accuracy and performance. These enhancements significantly improve the efficiency of CMM operations, making software upgrades an attractive option for many users looking to optimize their systems.

CAD-driven programming allows for seamless design-to-inspection workflows, making it easier to measure parts directly from CAD models. This reduces setup time and minimizes human error, as the CMM can automatically follow the design's specifications. The result is a more efficient, precise, and capable system that can handle a broader range of tasks, including complex and automated inspections, ultimately improving manufacturing quality and productivity.

VDMIS supports industry standards like the DMIS programming language and the I++ DME communication protocol, ensuring broad compatibility with CMM controllers.

Upgrading your CMM with VDMIS Software indeed offers a range of benefits. Here are some specific reasons why this decision can significantly enhance the performance and usability of your CMM:

This retrofit package essentially transforms your older CMM into a high-performance state of the art measuring system, extending its lifespan and enhancing its capabilities to rival modern systems. It's an excellent investment for those looking to maximize the potential of their existing equipment.